- [email protected]

- Call Us On: (0)1536 275000

RIM

We manufacture products for a range of industry sectors

Our extensive knowledge of polyurethanes and plastics can be applied to many industry sectors. Why not contact us today to see how we can help

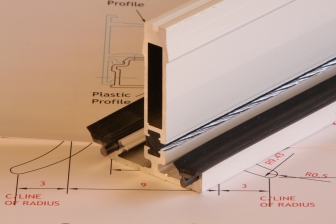

EXTRUSIONS

Rigid, flexible and Co-extruded profiles of varying density and hardness. Materials including PVC, TPE, LDPE, Nitrile, Glazepta and ABS can all be extruded

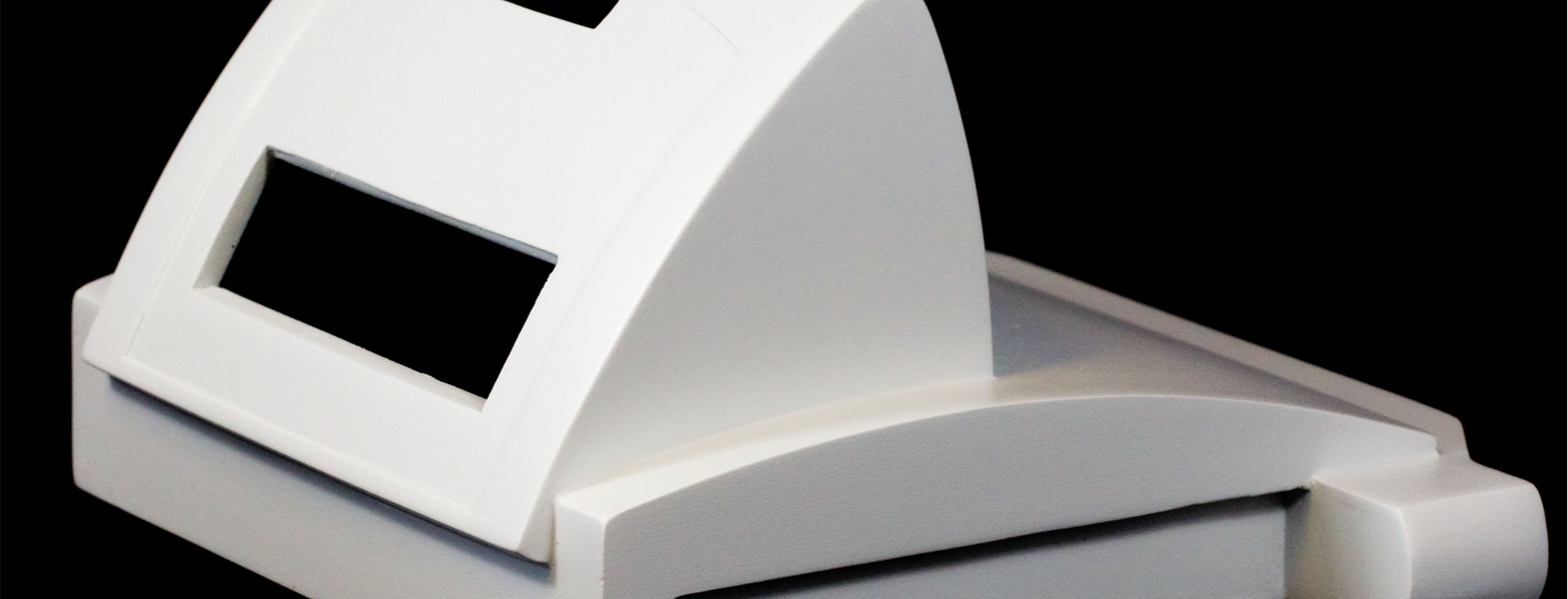

RIM

(REACTION INJECTION MOULDING)

(REACTION INJECTION MOULDING)

Our Reaction Injection Mouldings (RIM) process can be used to high precision casings, facia and enclosures that can finished and painted to your exact specifications with very low set up costs

POLYURETHANE FOAM

Polyurethane Foams can be moulded in a range of different densities and harnesses and flexibility to produce hard wearing parts with varying mechanical and physical properties